Your order will be processed in GBP.

[switch currency to EUR]

Product Availability: 5 - 10 working days

[switch currency to EUR]

| Order | Request an official quote (RFQ) |

|---|

Product Availability: 5 - 10 working days

AFM Probe type:

ARROW-NCPt

Manufacturer: NanoWorld

(https://www.nanoworld.com)

Product Description:

Optimized positioning through maximized tip visibilityNanoWorld Arrow™ NCPt AFM probes are designed for non-contact or tapping mode imaging. This probe type combines high operation stability with outstanding sensitivity and fast scanning ability.

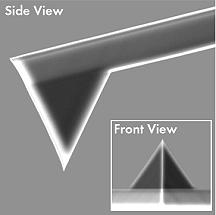

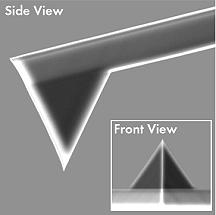

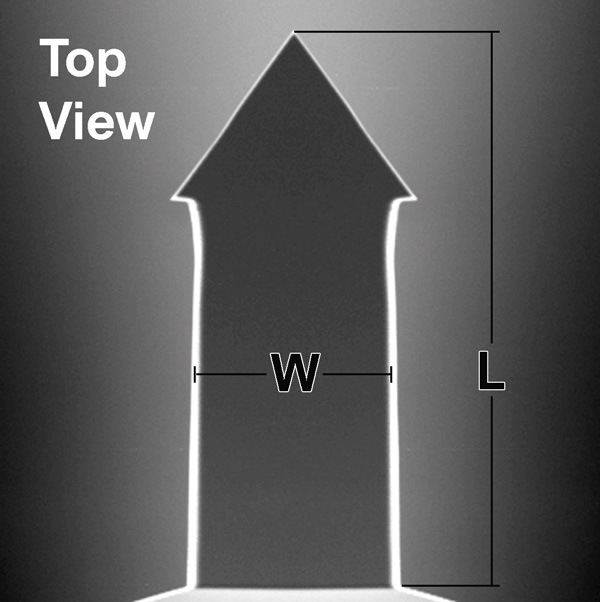

All SPM probes of the Arrow™ series are made from monolithic silicon which is highly doped to dissipate static charge. They are chemically inert and offer a high mechanical Q-factor for high sensitivity. The probes feature a rectangular cantilever with a triangular free end and a tetrahedral tip.

Additionally, this AFM tip offers an excellent tip radius of curvature.

The unique Arrow™ shape with the tip position at the very end of the cantilever allows easy positioning of the tip on the area of interest.

Application Modes:

AFM Probe Specifications:

AFM Tips:

| shape | tip height | tip set back | tip radius | full cone angle | half cone angle | |

|---|---|---|---|---|---|---|

| Arrow | 0 µm (10 - 15 µm)* | 10 - 15 µm* | 0 µm ( 0 - 0 µm)* | < 25 nm |

AFM Cantilever(s):

| cant. | shape | length | width | thickness | force const. | res. freq. | probe base |

|---|---|---|---|---|---|---|---|

| Beam | 160 µm (155 - 165 µm)* | 45 µm (40 - 50 µm)* | 4.6 µm (4.1 - 5.1 µm)* | 42 N/m (27 - 80 N/m)* | 285 kHz (240 - 380 kHz)* | ||

* typical range

Coating:

PtIr5 CoatingThe PtIr5 coating consists of a 23 nm thick platinum iridium5 layer deposited on both sides of the cantilever. The tip side coating enhances the conductivity of the tip and allows electrical contacts. The detector side coating enhances the reflectance of the laser beam by a factor of 2 and prevents light from interfering within the cantilever.

The coating process is optimized for stress compensation and wear resistance. Wear at the tip can occur if operating in contact-, friction- or force modulation mode. As the coating is almost stress-free the bending of the cantilever due to stress is less than 2 degrees.

**ScanAsyst® and Peak Force Tapping® are registered trademarks of Bruker Corporation.

*** Olympus® is a trademark of Olympus Corporation.

Apex Probes Ltd., 12th Floor, Ocean House, The Ring, Bracknell, RG12 1AX, Phone: +44 (0)1344 388016